3003 0 1100 0 6061 s0 5052 s0.

Bending 2024 t3 aluminum sheet.

Here we can see the density of the alloy.

Steel american iron and steel institute 1 see aisi s fabrication guidlines for cold bending thk 6061 t6.

18 8 type 302 020 063 063 063 063 063.

Bending 2024 t3 grain direction considered.

For this example an l channel made from 2024 t3 aluminum alloy that is 0 032 inch thick will be bent.

Order by part number.

Physical properties of 2024 aluminum.

As a 2000 series alloy 2024 aluminum is frequently heat treated to enhance its strength.

Some of the most common tempering options for this alloy are t3 t4 t351 and t851.

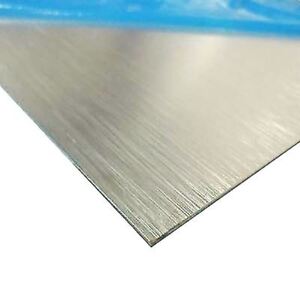

Qq a 250 5 2024t3 alclad aluminum sheet 2024 t3 this is the most common of the the high strength alloys.

5052 h32 5052 h34 6061 t4 2024 0.

Pieces 22 long by 1 75 wide by 0 63 thick.

Inside bend radius 0 19.

The minimum bend radius data shown in these charts is measured to the inside of the bend.

Aluminum where necessary 5052 h32 may be bent to 1t and 6061 t6 to 1 1 2t.

Material properties of 2024 t3 2024 t4 t351 2024 t851 aluminum.

Since commercial sheet metal bending can be done with less concern for stresses caused during forming operation the radius can be near zero for thin sheet metal.

Aircraft quality 2024 t3 aluminum sheet is thought of as the aircraft alloy because of it s strength.

Welding is generally not recommended.

Typical uses for 2024t3 alclad aluminum sheet are aircraft skins cowls aircraft structures and also for rv.

Any time a different thickness of sheet metal needs to be formed or when a different radius is required to form the part the operator needs to adjust the sheet metal brake before the brake is used to form the part.

With 2024 t3 040 sheets is there plastic on both sides for protection as you noted is the case for 2024 t3 025 sheets.

Minimum sheet size available is 2 x 4.

The bend radii listed are standard minimum if manufacturing for aircraft and aerospace applications.

The bend is along the long dimension.