You cannot change the radii of hems or offsets using the modify bends dialog box.

Bend sheet metal creo.

If i had to i would add the tongue after the bend feature.

Here end the fabrication formulas for sheet metal up next we ll be seeing some of the terminologies in sheet metal that you ll need.

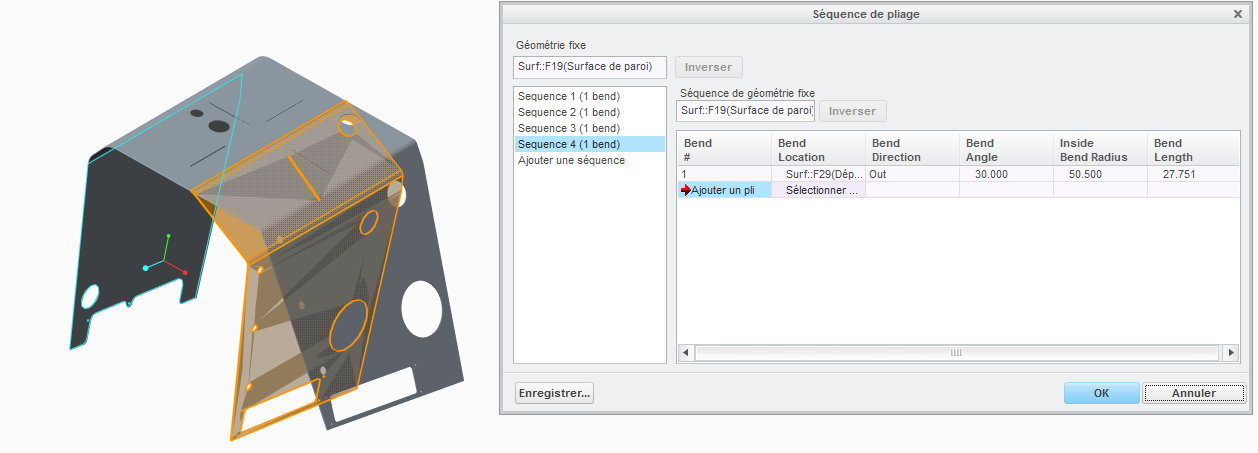

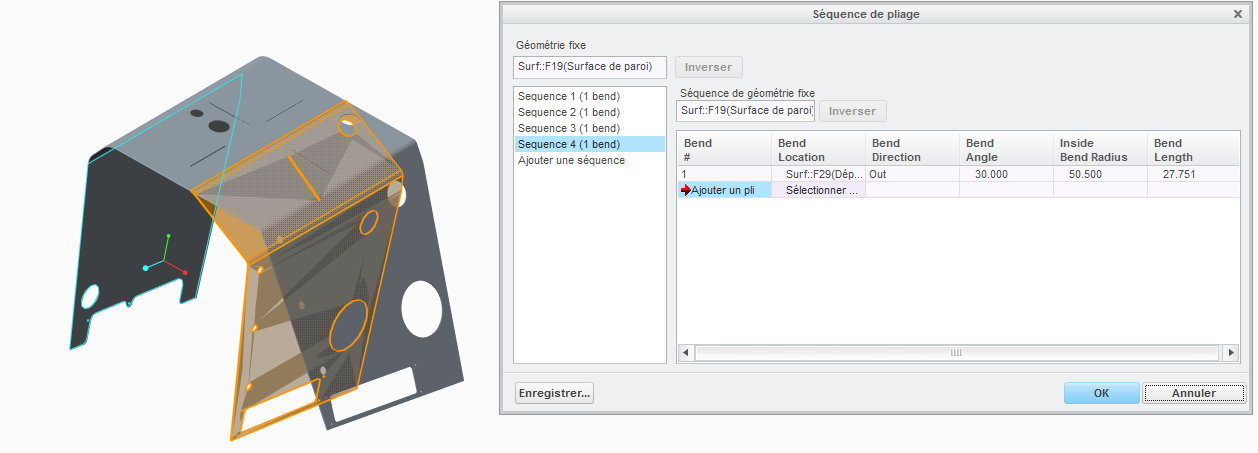

Start by selecting the bend surface.

If you wish to increase the bend radius beyond the upper limit of the existing bend reliefs you must first modify the bend reliefs to accommodate the increased radius.

Click edit bendin the mini toolbar.

Another important sheet metal feature is a bend.

Get to know them better to learn advance concept easily.

0 kudos reply.

Sheet metal drawings usually contain views both of the fully formed partand of the flat pattern as in figure sm 4.

Creo sheet metal tutorial sheet metal bracket 1 in creo parametric duration.

What is the method to create sheet metal bend that has a flat area as shown since bend line in sketch must be one entity.

Welcome to mcad central join our mcad central community forums the largest resource for mcad mechanical computer aided design professionals including files forums jobs articles calendar and more.

Overview this comprehensive suite of creo sheet metal design tools helps users create features such as walls bends punches notches forms and relief features.

Using a variety of y and k factor bend allowance calculations designers can create flat patterns of the designs.

Bends are often generated automatically during the creation of wall features.

In general creo elements direct sheet metal allows you to change the radii and the bend processes of bends.

So what i did was build the extrude converted it to sheet metal driving surface and then added a bend feature selecting one of the end edges as the bend line the bend radius would be change from thickness to whatever diameter you are wrapping the label on to.

I thought they added something for this in creo 3 0.

Editing a bend now that you have a sheet metal part just go to the edit bendcommand.

Sheet metal modeling and drawing with bend table.

Bend line shift bls the distance from the outside mold line to the original bend line on the flat pattern this is used to calculate the backstop location when working off of a flat pattern.

Anything to do with sheetmetal.